304 vs 316 Stainless Steel and Metal Processes

When it comes to building boats, manufacturers like to use a variety of construction materials that are durable, long-lasting, and of course, affordable. When it comes to comparing the differences between one material to the next, there’s an obvious difference in looking at a plastic vs a metal—but in comparing one metal to another, the distinctions might not be so easily recognizable.

One of the most commonly used materials in boat construction is marine grade stainless steel. It’s sturdy, reliable, attractive, easy to maintain, and in most cases, it stands the test of time against everyday wear-and-tear. So, what makes one type of stainless steel better than the other?

Let’s find out by comparing two of the most popular marine grade stainless steels: 316 stainless steel vs 304 stainless steel.

Similarities in 304 Stainless Steel and 316 Stainless Steel

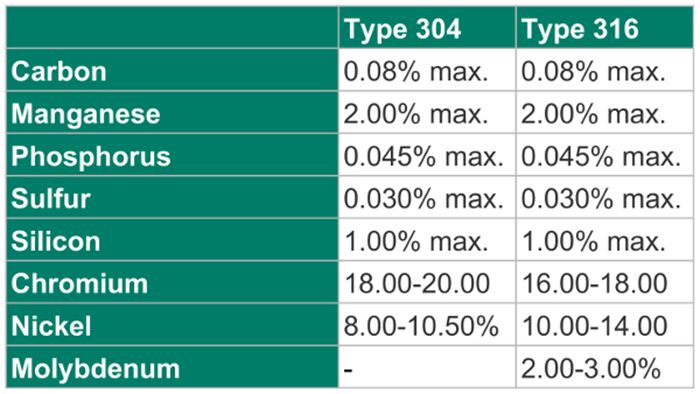

In general, all marine grade stainless steel—which is typically in the 300-series range—is universally valued for its ability to fight corrosion thanks to one critical ingredient: chromium. Chromium helps to create a tough film on the surface of the metal, which can become even more protective and thicker when the stainless steel is polished. Both stainless steel 304 and 316 have similar levels of chromium in their composition.

Likewise, both types of stainless steel are not magnetic. To the average boat owner, the differences are almost impossible to notice at a surface level.

Differences in Composition

The biggest difference in looking at the properties of 304 stainless steel vs 316 has do to with composition. Stainless steel 316 tends to have a slightly higher nickel content, plus an addition of molybdenum to better resist and withstand corrosion—which is why 316 stainless steel is typically more costly than 304.

Benefits & Applications of Different Marine Grade Stainless Steel

As just mentioned, in looking at 316 stainless steel vs 304, you’ll find that the price tag is slightly higher for 316—but it’s worth it. Although 304 is a strong, versatile metal that can be used for many different purposes onboard, 316 is the premium option. This is because it includes the additional protection against chlorides and similar chlorinated solutions, which is fundamental in fighting corrosion from saltwater.

For any use-cases involving highly corrosive solutions like chloride, brine, sulfuric acid, bromides, iodides, and other fatty acids, boat owners will want to opt for the superior choice in stainless steel 316.

To put it simply, if you’re a saltwater boater, you’ll want the extra protection offered by 316 against salt spray, ocean air, and salty residue; however, for freshwater and inland boaters where saltwater is not a concern, 304 stainless steel is just as reliable. Stainless steel 304 has also been commonly used for components that don’t have any saltwater exposure, such as for interior uses. Anything on deck and below the waterline should always utilize 316.

Lastly, if you’re looking to take things a step higher than 316, you can also consider using 316L stainless steel, which is known to have less carbon content to avoid carbide precipitation in welds.

For all your high-quality stainless steel marine hardware needs and replacement parts, be sure to visit Marine Depot Direct. And, don’t forget to read our related blog on Cleaning Your Stainless Steel Boat Parts.